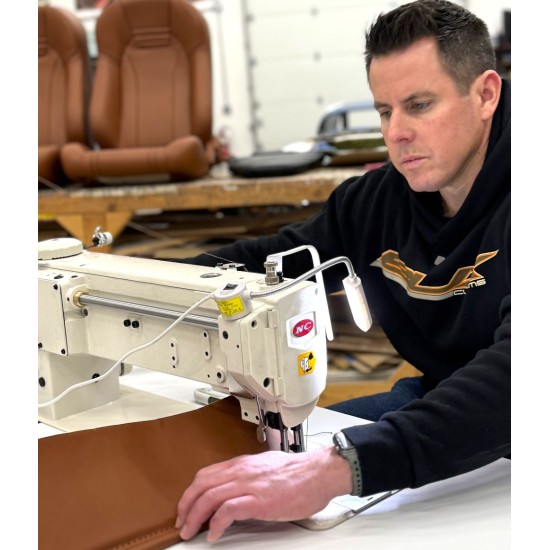

The extended 18" long arm gives upholsterers the working room they need for larger projects such as car and aircraft seats, custom furniture, marine cushions, motorcycle seats, and high-end headliners. This added space under the arm allows fabricators to maneuver bulky materials more comfortably and efficiently, reducing operator fatigue and boosting throughput. Whether you’re sewing vinyl-wrapped panels, laminated leather, or multiple foam-backed layers, the NC18L accommodates these challenges without compromising stitch quality or speed.

What sets the NC18L apart for upholstery professionals is its true compound walking foot mechanism. This system delivers synchronized feeding from the presser foot, needle, and feed dog, ensuring layers of material move together consistently—preventing slippage, skipped stitches, or misaligned seams. When working with slick vinyl or soft-backed materials, the compound feed ensures uniform stitching across the entire seam, even on curves or pleated sections.

The machine’s built-in foot control knob is a true asset in real-time adjustments. As many upholstery jobs require frequent transitions between different thicknesses—think piping seams, bolster seams, or foam-layered components—this feature allows the operator to instantly raise or lower the presser foot clearance to accommodate these transitions without pausing production. Combined with a generous 16mm foot lift, the NC18L offers superb accessibility and adaptability during complex or layered stitching.

The NC18L is also fitted with a double-capacity vertical axis rotary hook system, which not only holds more thread than standard bobbins (reducing changeover time) but also offers more stable tension and balanced stitching—critical for jobs where long seams or decorative topstitching is required. The large bobbin is ideal for high-volume shops that don’t have time for frequent bobbin changes, making this machine a time-saving investment.

To safeguard the machine during heavy workloads, the NC18L comes standard with a safety clutch mechanism that disengages the hook if thread jams or needle breaks occur. This protective feature helps extend the machine’s lifespan and reduces costly repairs due to hook damage.

Every NC18L is paired with a high-speed servo motor that provides silent operation, responsive speed control, and full torque even at low speeds—perfect for precision tasks like edge sewing or tight corners. Combined with the machine’s built-in bobbin winder and a rugged, USA-made solid wood table, the NC18L is built for daily, industrial-grade use in even the busiest upholstery shops.

In short, the NC18L delivers everything an upholstery professional needs: extended reach, smooth feeding, high lift clearance, exceptional stitch control, and rugged reliability. Backed by a 2-year limited warranty and tested by industry leaders like Chris McClintock of Bux Customs, this machine is a must-have for shops looking to level up their capabilities and take on more complex, higher-margin work.

Shop 18" long arm walking foot sewing machines from NC Carpet Binding. Our industrial long arm sewing machine is designed for upholstery sewing.